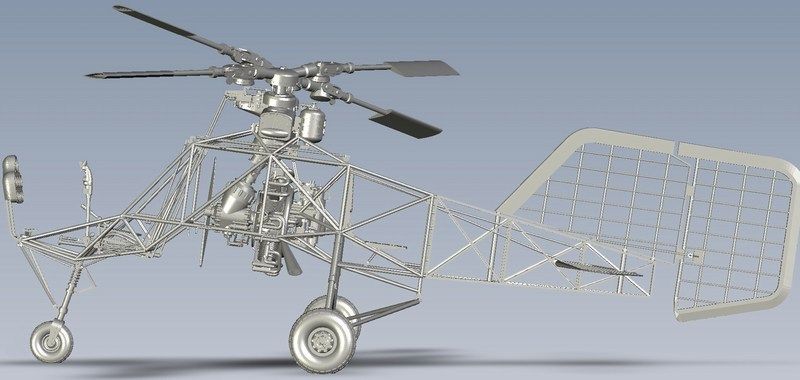

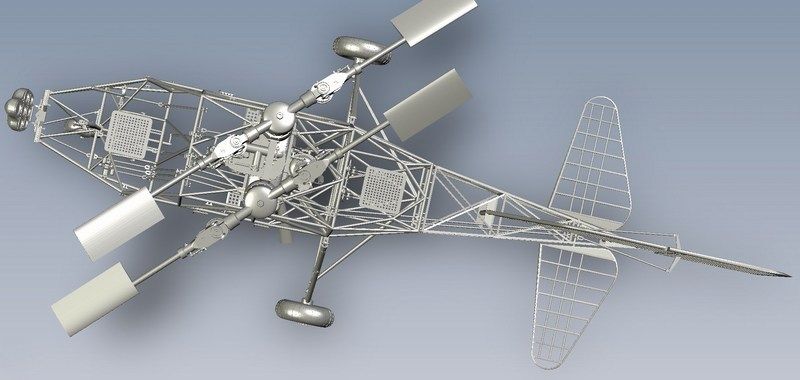

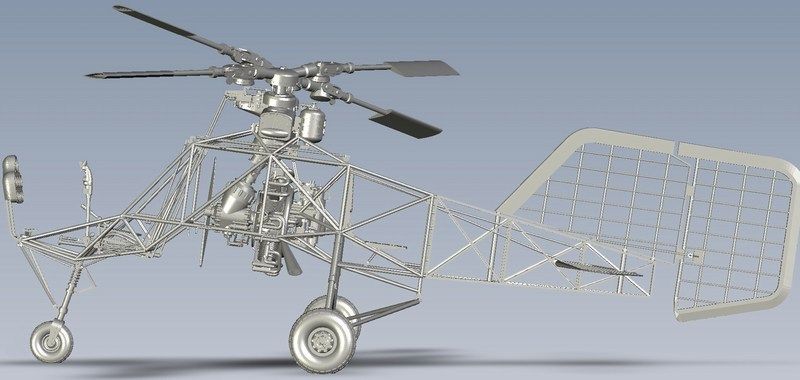

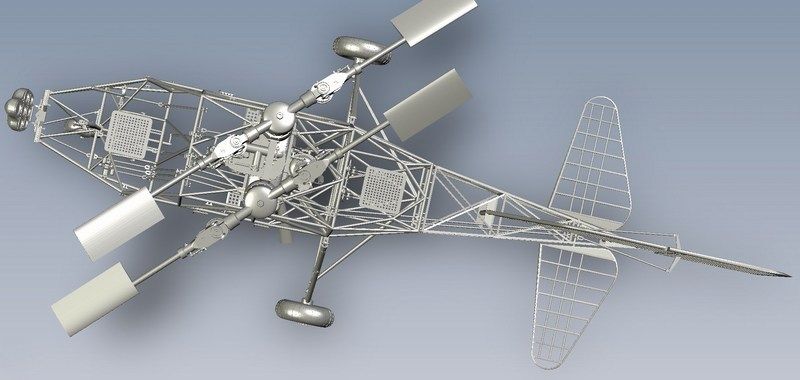

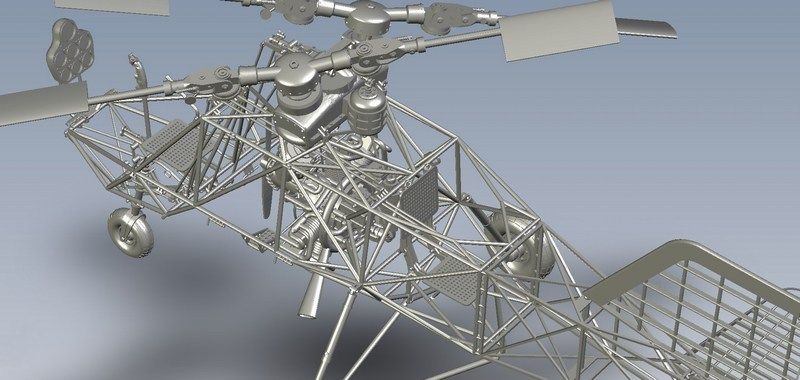

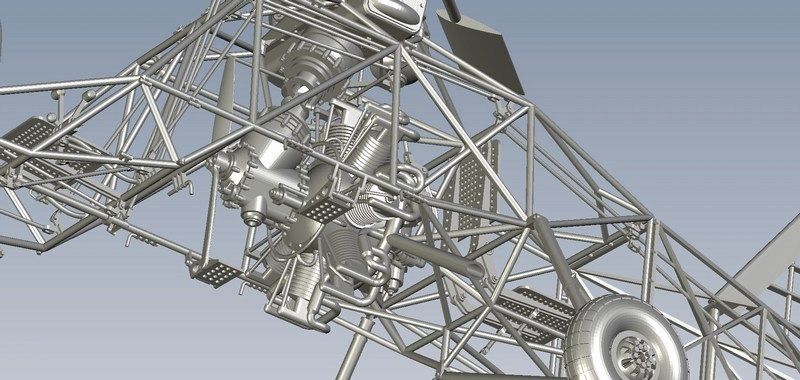

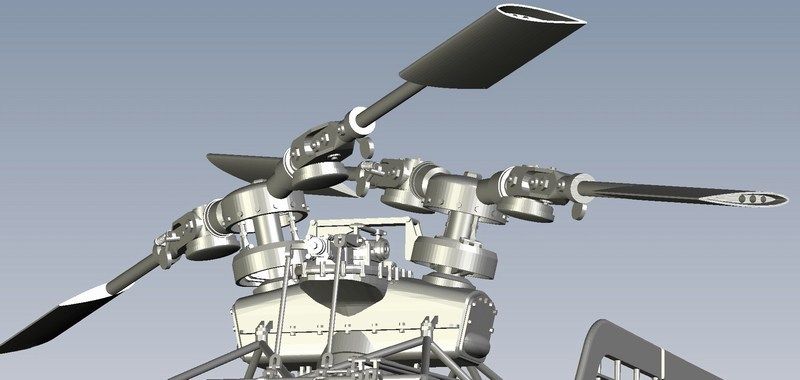

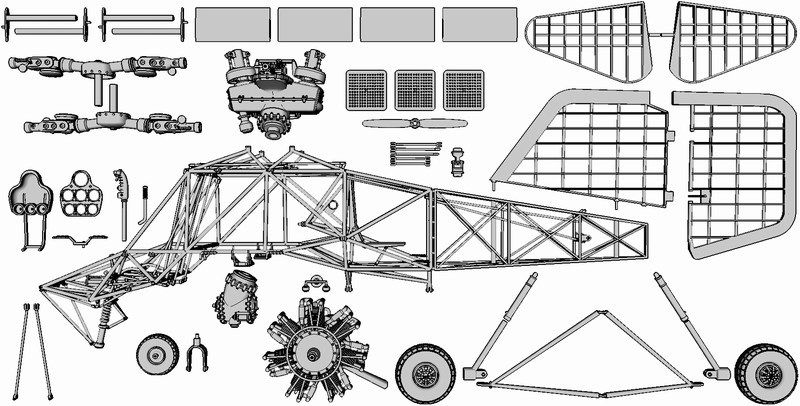

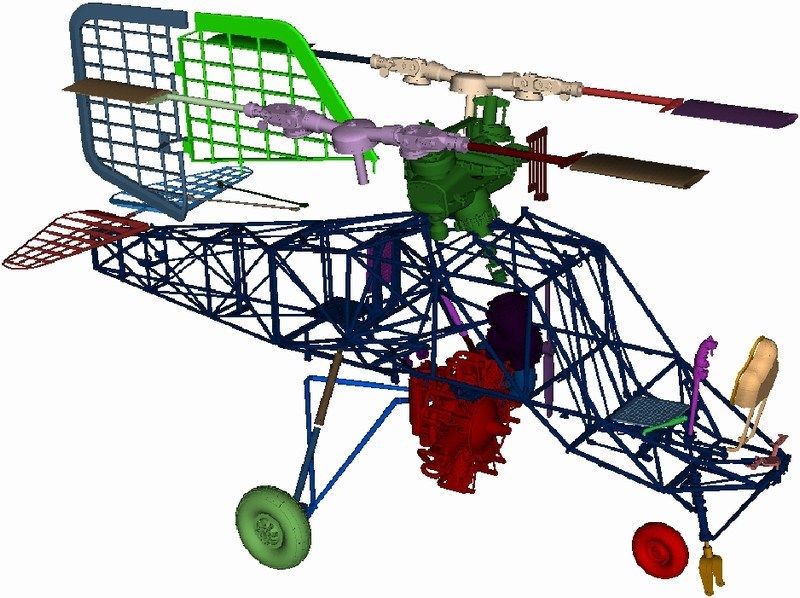

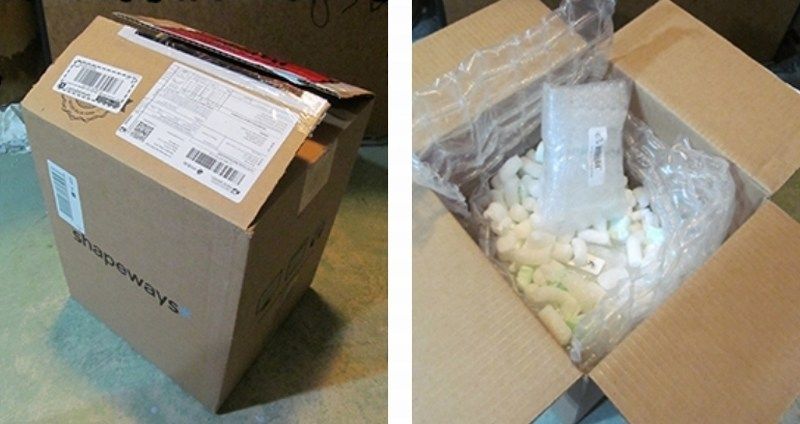

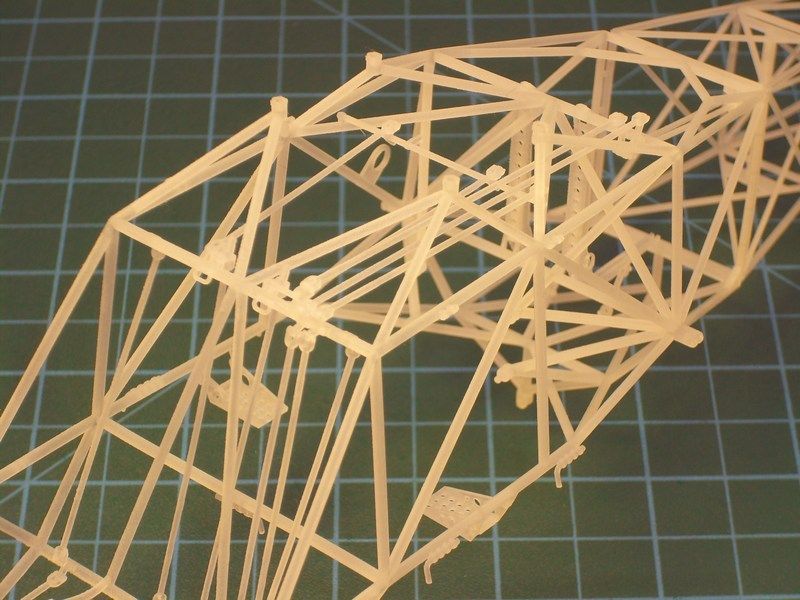

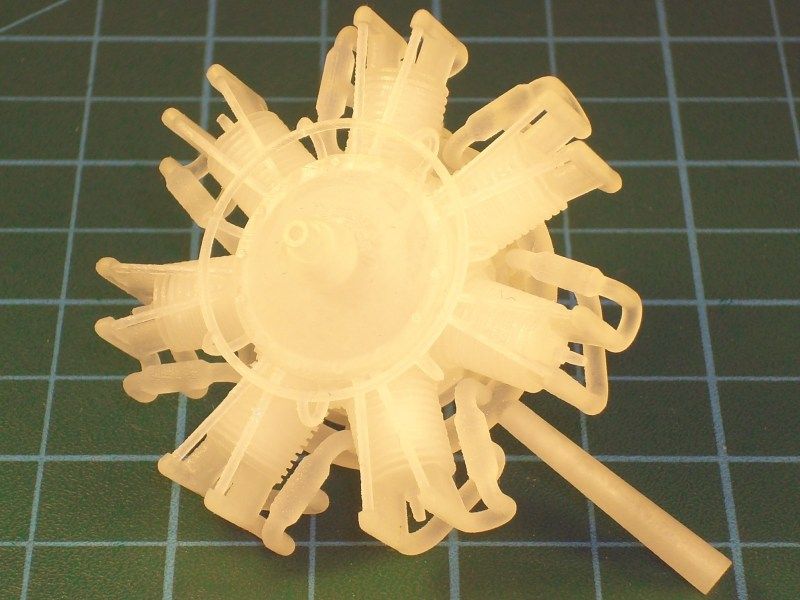

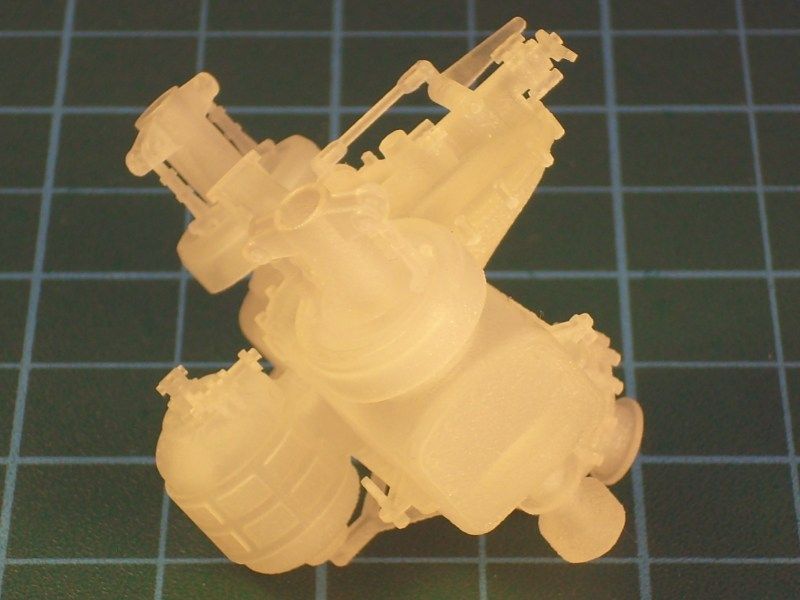

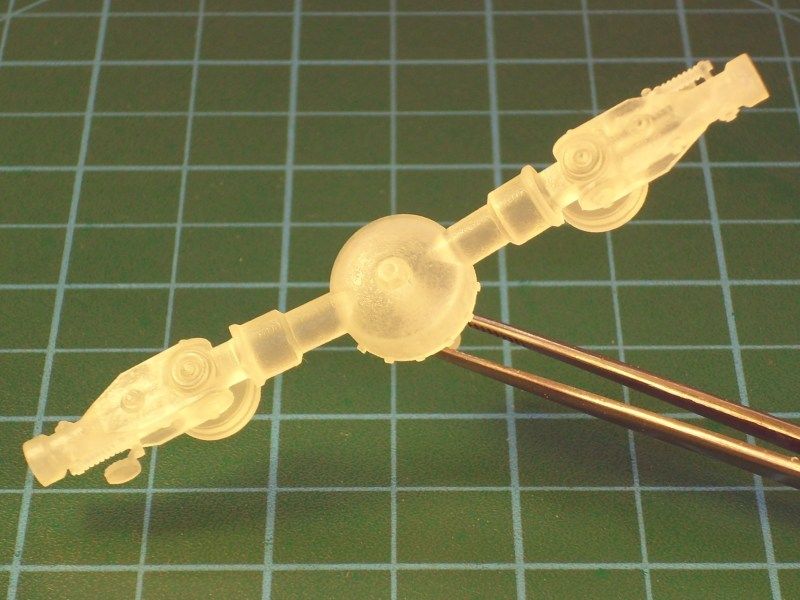

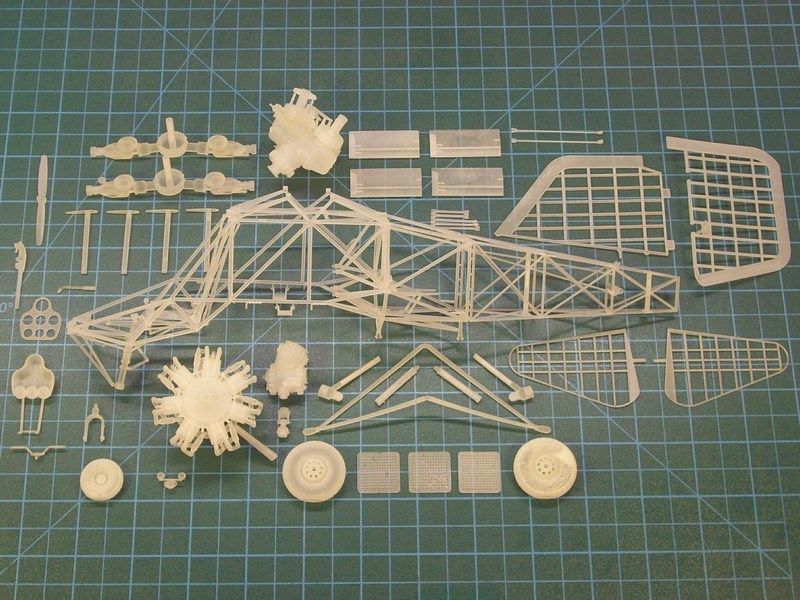

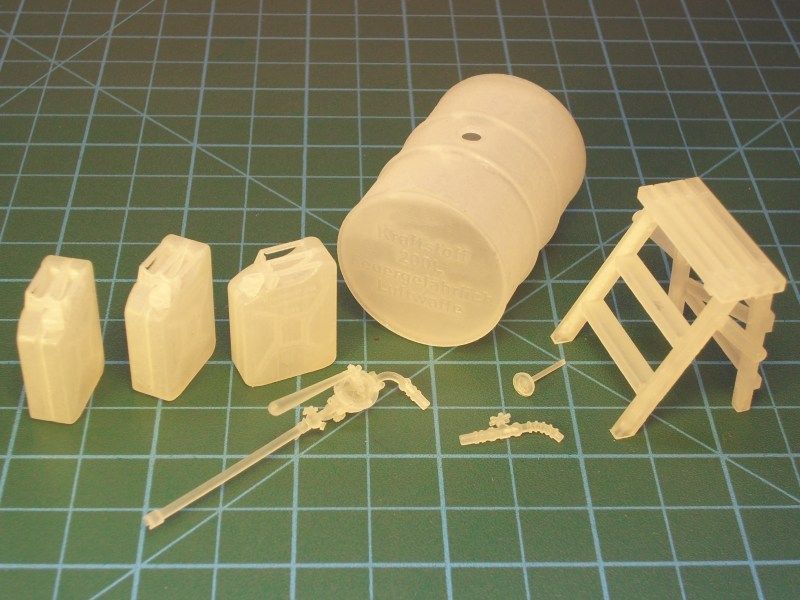

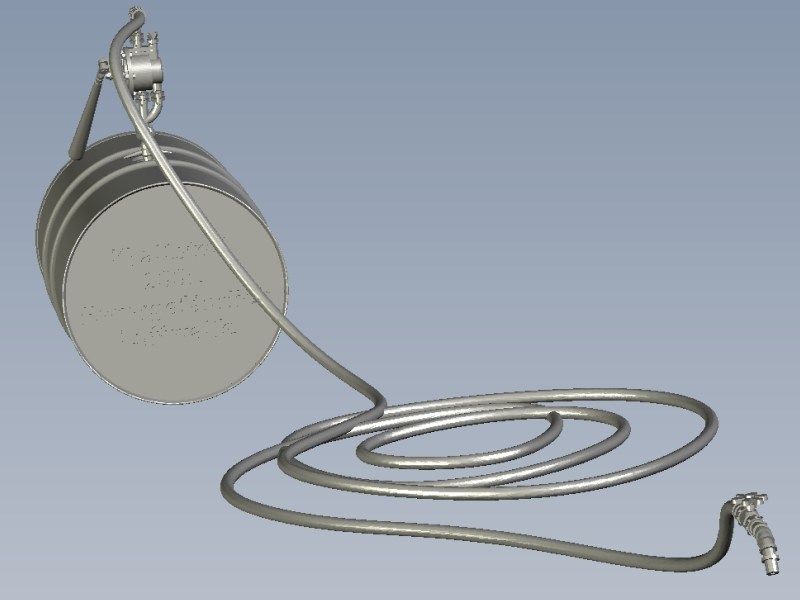

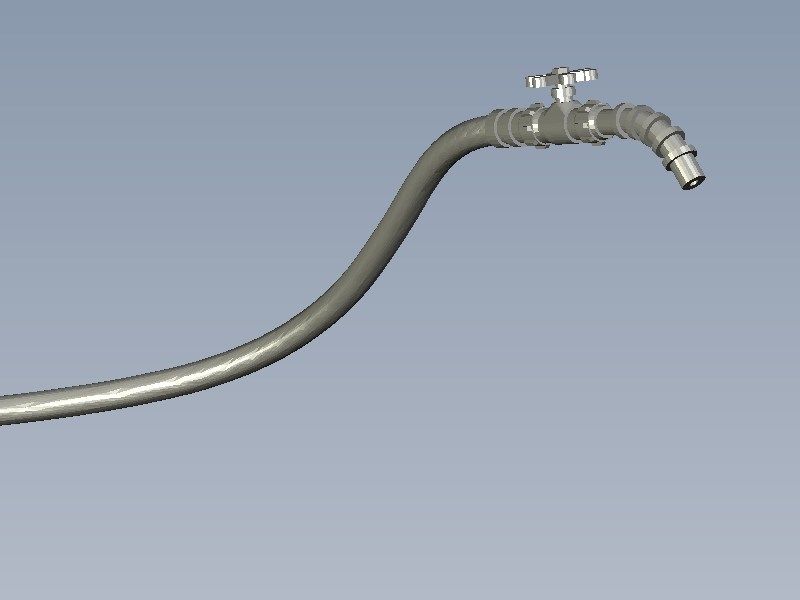

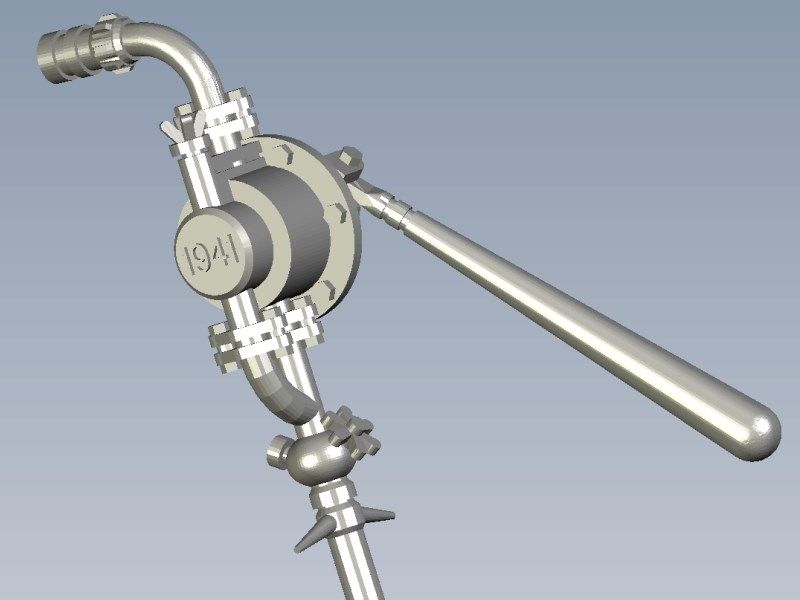

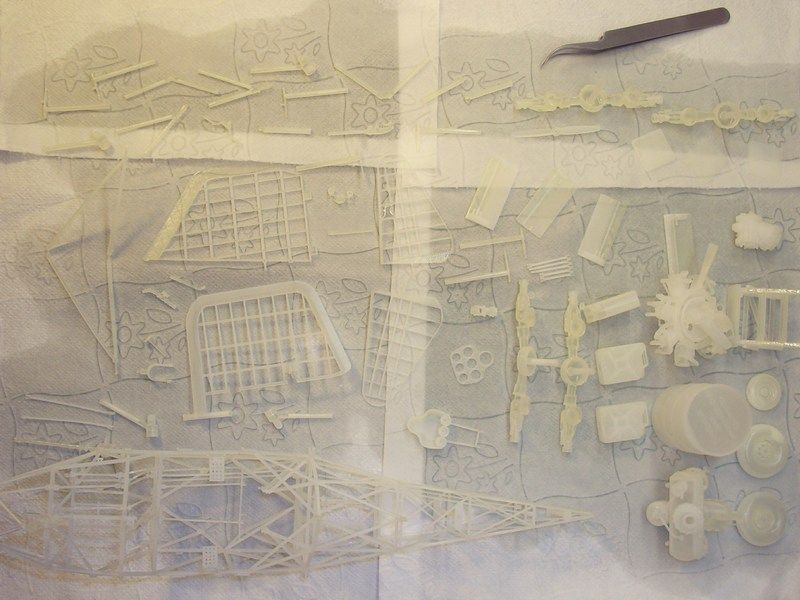

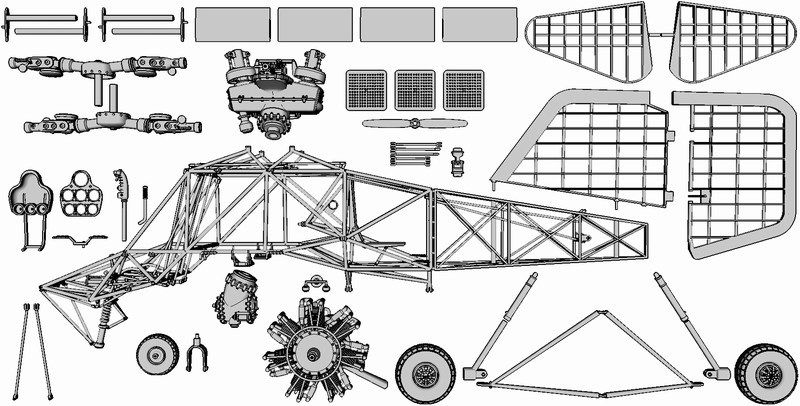

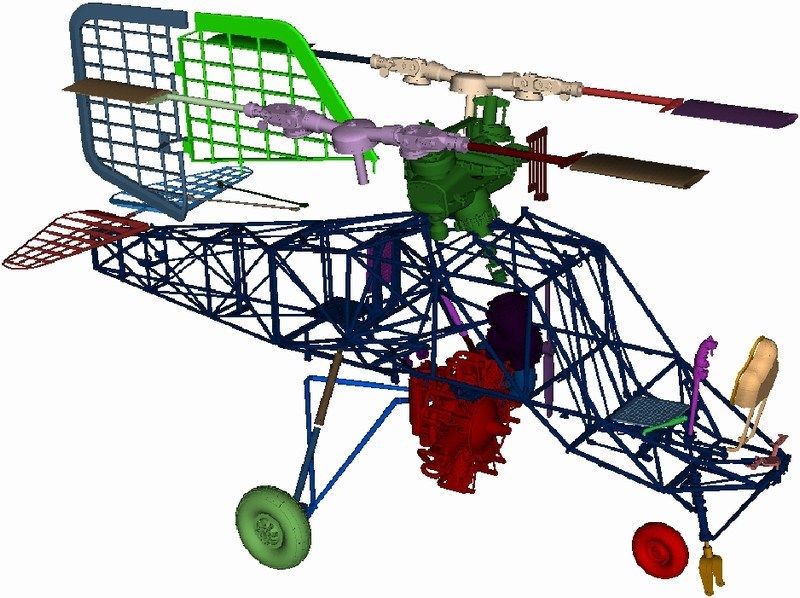

After digitally building the Fl-282 Kolibri cutaway 3D model using only mouse clicks, I saved it as an STL - STereoLithography format binary file and forward it on the 3D replicator to start generating the individual parts of the actual scale model. Once again, I used best available tools & plastic material and asked from Shapeways digital fabrication lab (equipped with a high-precision & high-cost “ProJet HD 3000” machine for creating custom made-to-order products), to 3D print it. The 1/18 scale Fl-282 V21 Kolibri “cutaway” model kit consists of more than 40 different 3D printed parts made of matte translucent plastic material - in fact, the kit parts are quite more, but smaller in size are interconnected on same sprue frame which is counted as one part. Kit was CAD designed and 3D produced in such way to simplify assembling process while maintaining necessary details required by the scale size. Following the instructions described into the 67-page ultra-detailed “

1/18 Fl-282 V21 cutaway kit building instructions” manual (which can be found

HERE as a PDF format downloadable file), the assembling process becomes easy.

When printing is finished, the model parts are removed from the tray and placed into an oven that melts away the wax support material. Next, the models are placed into an a ultrasonic oil bath to remove any remaining wax residues, and then a ultrasonic water bath to remove any oil on the model. Final inspection and dry by hand follows for every single model part. Although the ProJet HD 3000 prints in high resolution (16 microns per layer) and can easily produce high detailed parts as small as 0.1 mm, it is better to avoid printing such small parts because they could easily get lost while washed into ultrasonic bath later, for wax residues removing. Each complete model kit takes about 5 to 7 days to get produced after order due to increased workload for 3D printed manufacturing demand in Shapeways factory.