Page 1 of 3

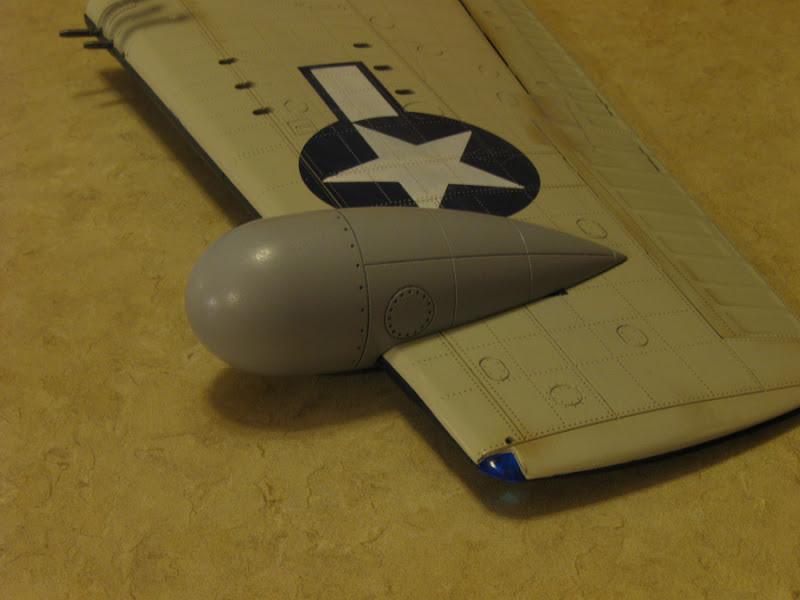

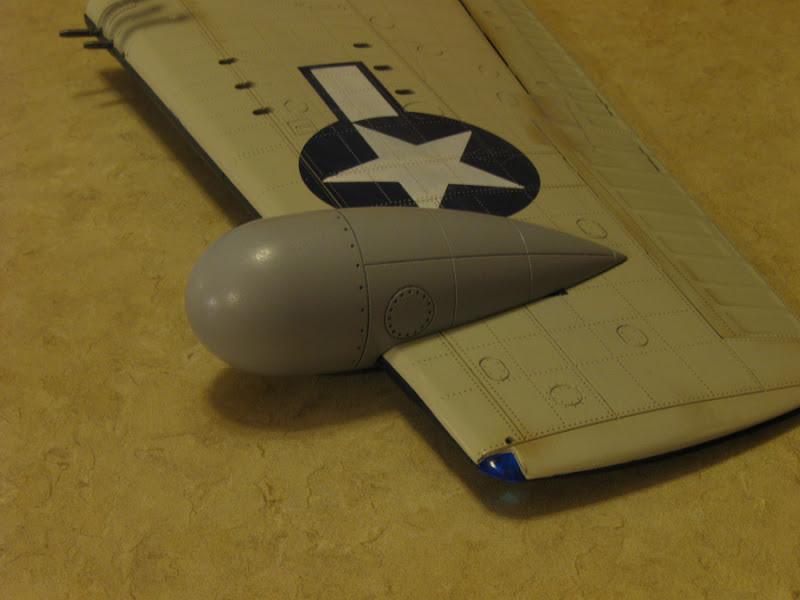

Hellcat Radar Pod: Available for Purchase

Posted: Mon Oct 03, 2011 9:41 pm

by aae83

Re: Hellcat Radar Pod - 3D printer project

Posted: Mon Oct 03, 2011 10:23 pm

by smittyrob64

Beautiful job, how much did the fabrication cost. I have CAD skills as well but never thought this route would be cost effective. If the cost to do something like this is, then I would like to try it also.

Re: Hellcat Radar Pod - 3D printer project

Posted: Mon Oct 03, 2011 10:53 pm

by Jnewboy

Nice! How much??

Re: Hellcat Radar Pod - 3D printer project

Posted: Tue Oct 04, 2011 4:23 am

by gburch

Beautiful work! Welcome to the "citizen craftsman" revolution, comrade!

My dream is coming true!!!!!

Re: Hellcat Radar Pod - 3D printer project

Posted: Tue Oct 04, 2011 10:35 am

by aae83

gburch wrote:Beautiful work! Welcome to the "citizen craftsman" revolution, comrade!

Thanks, Greg. Glad to be a part of it.

Relative to the cost, this piece cost $25 which, not coincidentally, is the minimum order amount set by shapeways. The unit cost was a little less than that, so I had to throw something extra into my cart to bring the order up to the minimum. The good news is their price includes shipping/handling, and they overnight it when it's done (from order placement to actual delivery nominally takes 10 business days).

Here are some design/fab particulars that influence the cost:

Material: This part was made in Alumide (a vinyl/aluminum blend) because I didn't have any experience with their material and was concerned about making something out of a material with a descriptive name that included the word "flexible" (WSF-White, Strong and Flexible). Alumide is priced at $1.99/cc and WSF is $1.50/cc. Changing materials to WSF would save ~25%; however, WSF is unproven in this application, at least for me.

Thickness: The minimum wall thickness for Alumide is 1.5mm (approx. .059"), so that was what I used. The minimum thickness for WSF is 0.7mm, so the part could have been made with about 50% less material, if designed specifically for WSF. Redesigning the part with thinner walls would take (me) about an hour or so. Would be an interesting exercise, though.

Thus, using the constraints of WSF, one could expect to get the price down in the $10-12 range per part. You'd still have to buy at least two and/or add something else to your cart to get to the $25 minimum.

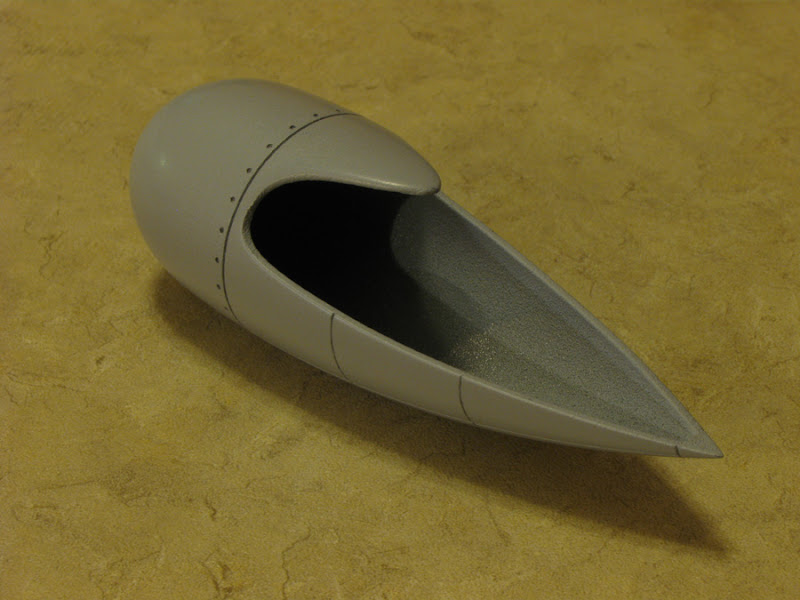

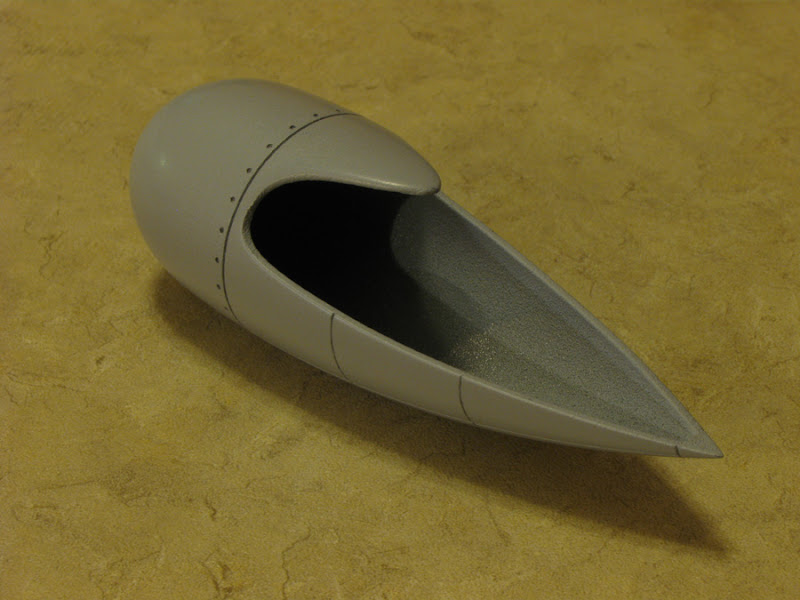

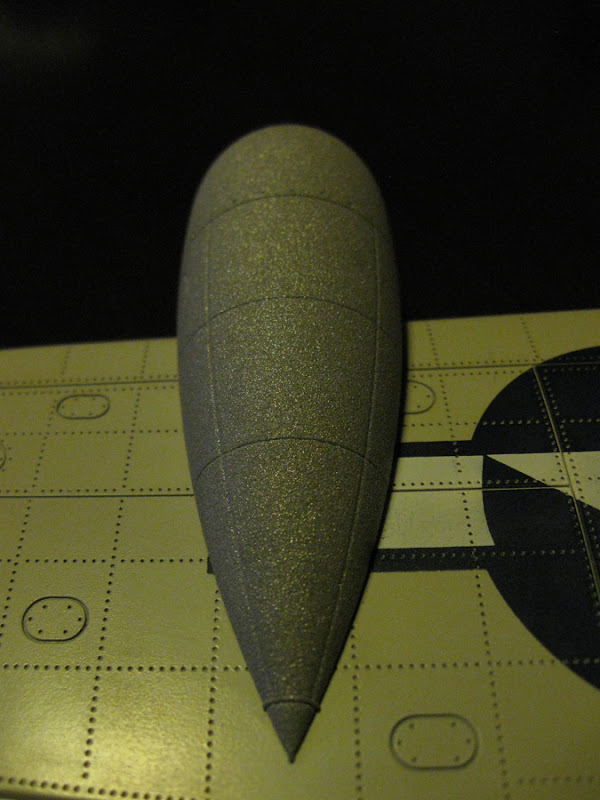

The part comes from shapeways literally in a "rough" form: it feels like about 220 grit sandpaper (see the photos showing the interior of the part). A little work is required to sand and smooth the exterior with primer/filler, similar to what Greg has shown in his Val thread. The putty isn't necessary with the SW part, however (my experience).

Given the cost and the effort (even minor as it is) to finish the surface of the part, I don't see SW as cost- or effort-effective for final part production. Am looking to take this process to the next level, using a smoothed part as a master pattern for mold production and casting copies. But that's a story for another day.

- aae

Re: Hellcat Radar Pod - 3D printer project

Posted: Tue Oct 04, 2011 10:41 am

by tmanthegreat

That looks great!

There's a custom of a night fighter Hellcat flown by USMC ace R. Bruce Porter (my father knew him and I have a signed autobiography) that I've been toying with doing. Not only do I need another BBI Hellcat, but I need a radar pod just like the one you made

Re: Hellcat Radar Pod - 3D printer project

Posted: Tue Oct 04, 2011 1:28 pm

by pickelhaube

So did you have to scribe the panel lines and rivet holes ?

The part looks great !!

Re: Hellcat Radar Pod - 3D printer project

Posted: Tue Oct 04, 2011 4:09 pm

by grunt1

That looks fantastic. I use WSF which works pretty well and it truly is very strong and flexible which is great for "toys" like 1:18 scale military items. Shapeways has a polished WSF that takes some of the roughness out and is more injection molding quality. There is also frosted ultra detail if you want the highest resolution but it is very brittle, might be a good mold master though, haven't tried it for that.. Alumide is about the worst, other than sandstone for texture and the amount of smoothing via post-printing squadron putty repair.

They allow you to buy a materials sample kit for about $30 so you can get a feel for the materials. Not all of them are included though.

Re: Hellcat Radar Pod - 3D printer project

Posted: Tue Oct 04, 2011 5:50 pm

by aae83

Thanks, all, for the kind words!

grunt1 wrote:I use WSF which works pretty well and it truly is very strong and flexible which is great for "toys" like 1:18 scale military items. Shapeways has a polished WSF that takes some of the roughness out and is more injection molding quality. There is also frosted ultra detail if you want the highest resolution but it is very brittle, might be a good mold master though, haven't tried it for that.. Alumide is about the worst, other than sandstone for texture and the amount of smoothing via post-printing squadron putty repair.

They allow you to buy a materials sample kit for about $30 so you can get a feel for the materials. Not all of them are included though.

That's good to know about the WSF. Before placing my first order I got the sample kit, which came with a $25-off coupon so in the end it only cost $5. Based on what I saw from the sample kit, I made the decision to go with the Alumide, the sample of which felt smoother to me than the WSF. I also thought the Alumide, being more brittle, might machine/polish better, as I felt was going to be needed in either case. I was quite happy with the part in Alumide but, apparently either works, which is great news, because that will save on cost! Do you use 0.7mm for your wall thickness?

The polished WSF ($1.75/cc) is a little more expensive than WSF ($1.40/cc, turns out) and cheaper than Alumide ($1.99/cc), but adds to fabrication time (total of 18 business days). I think there are more restrictive size limits for the polished, also.

Frosted Ultra Detail is significantly more expensive ($3.49/cc), but could be justified for small, highly detailed parts (like the APS-6 radar unit itself? hmm...). Part production in that material has been running behind, so there may be looong waits for parts (2.5 weeks behind). Also unfortunate, FUD is not in the sample kit, but instead three different colors of regular Detail material are - go figure.

pickelhaube wrote:So did you have to scribe the panel lines and rivet holes ?

The panel lines and rivet holes were built into the model but did need to be reinforced a bit. I used a simple scribing pick to trace the lines and a pin vise/drill bit to clear the holes. I also did this a little bit after the primer coats to make certain the detail remained. I'll post in progress photos so you can see exactly what it looked like out of the box and along the way.

tmanthegreat wrote:There's a custom of a night fighter Hellcat flown by USMC ace R. Bruce Porter (my father knew him and I have a signed autobiography) that I've been toying with doing. Not only do I need another BBI Hellcat, but I need a radar pod just like the one you made

Depending on how soon you (or anyone else) needs one, I could open up the part "for public sale" on the shapeways site (delivered cost $25, you have it in hand in 10 business days, and have to smooth it yourself). I plan to mold/cast some copies (which I'd expect to be significantly less expensive and not require any finishing other than painting), but that's less determinate, timewise: hopefully, no more than a week or two, though. I'm also going to try the WSF approach with a 0.7mm thickness, so that's another possibility, but this model is unproven in that thickness; we'll know in 10 business days, if I get an hour free tonight.

In progress photos soon.

Cheers.

Re: Hellcat Radar Pod - 3D printer project

Posted: Tue Oct 04, 2011 10:12 pm

by aae83

Looks like shapeways has just changed their pricing model: instead of charging a flat rate per unit volume plus a startup fee and no separate shipping fee, with a minimum $25 order, they're eliminating the minimum order but adding a fixed shipping fee ($6.50 to the U.S. and Canada, for example). Note they currently ship via UPS, who apparently charge a delivery fee in Canada.

I was able to get the unit cost of the radar pod down to just under $11 (before s/h) in WSF with a 1mm thick wall. I couldn't make the walls 0.7mm without endangering the part near the panel lines.

Am not going to order it at the moment though: it's not worth the extra $6.50 to me to see it in the flesh. I'll add it in when I'm ordering something else.

- aae

Re: Hellcat Radar Pod - 3D printer project

Posted: Wed Oct 05, 2011 1:38 am

by grunt1

My larger challenge has been with smaller details, rods, control wheels, etc.. and bringing them up to at least .7mm with them looking out of scale. .7mm would need to be everywhere as you indicated not just the overall part thickness with the panel lines being < .7mm. I've found that they reject a lot of stuff because of that.

The other issue is that .7mm versus 1mm may not seem like a lot, but if you factor it as almost a 30% decrease in your model cost (ie, $65 versus $100 for a larger model) it adds up fast.

I'm glad they finally adjusted the shipping arrangement, now they just need to discount for volume.

Re: Hellcat Radar Pod - 3D printer project

Posted: Wed Oct 05, 2011 9:05 am

by flyboy_fx

Lord I want one of those!!!!!!

Re: Hellcat Radar Pod - 3D printer project

Posted: Wed Oct 05, 2011 10:16 am

by aae83

flyboy_fx wrote:Lord I want one of those!!!!!!

Am guessing you mean the cannon and not the radar pod.

The cannon is, indeed, very cool. I imagine a fabrication shop is pretty much the only way to go with one of those. Nice piece, grunt1!

Re: Hellcat Radar Pod - 3D printer project

Posted: Wed Oct 05, 2011 11:16 am

by JOC

Sign me up now for three of those pods.

JOC

Re: Hellcat Radar Pod - 3D printer project

Posted: Wed Oct 05, 2011 5:34 pm

by flyboy_fx

aae83 wrote:flyboy_fx wrote:Lord I want one of those!!!!!!

Am guessing you mean the cannon and not the radar pod.

The cannon is, indeed, very cool. I imagine a fabrication shop is pretty much the only way to go with one of those. Nice piece, grunt1!

Oh yea I want the cannon! But I was talking bout the pod!!! It is fantastic! If I only had a wildcat.

Re: Hellcat Radar Pod - 3D printer project (IMG heavy)

Posted: Wed Oct 05, 2011 8:49 pm

by aae83

Re: Hellcat Radar Pod - 3D printer project

Posted: Thu Oct 06, 2011 4:54 am

by grunt1

Never TMI, keep it going! The updated pod looks great.

Re: Hellcat Radar Pod - 3D printer project

Posted: Sun Nov 20, 2011 3:18 pm

by JOC

Any more information on when the pods will be available for sale?

Thanks

JOC

Re: Hellcat Radar Pod - 3D printer project

Posted: Sun Nov 20, 2011 5:20 pm

by aae83

Hi, JOC. Thanks for your patience and continued interest!

Have made some progress on the casting side of things, and hope to have parts available for sale "soon," maybe as soon as the week after Thanksgiving(?). Outside life has taken priority, and have also been working on the mold-making and casting processes to iron out aspects I wasn't fully satisfied with. Most recently, have been working with the casting process, trying to get a reliable, clean, bubble-free casting. My goal is to be able to pull the part from the mold with little more clean-up than would be required from a quality injection molded part.

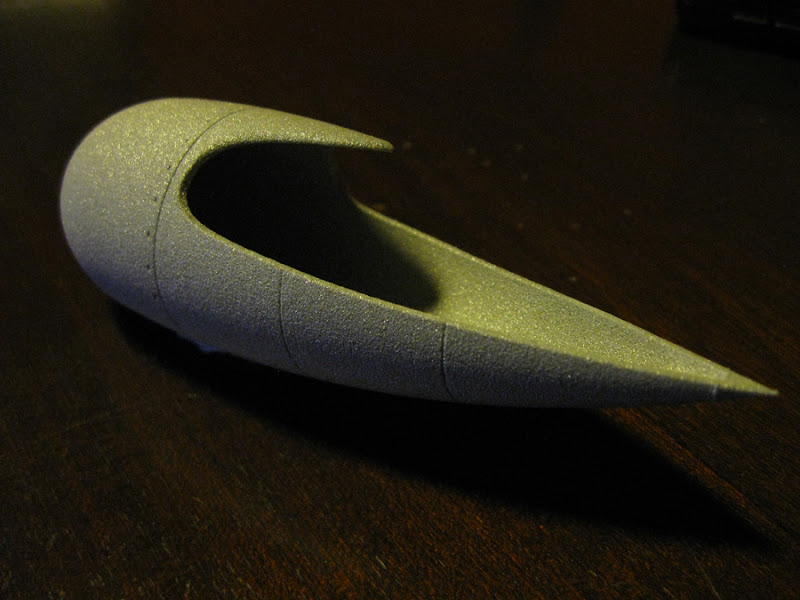

Here are some photos of castings from my first generation mold. The good: I've got the parts coming out cleanly, with almost zero flash, capturing the finish and panel/rivet detail. The not so good: there are bubbles in the parts. You can see them in the left and right examples; they're on the back side of the center part.

Someone with a little modeling skill and energy could smooth the bubbles down and, if necessary, fill them. However, I'd prefer to tweak the mold as needed to make this part paintable straight from the mold (after a quick washing), rather than create any unnecessary work for people. I think all that's needed is a larger gate into the mold to let the air out, and to re-orient the mold cavity to facilitate air/resin flow.

Time permitting in the next couple of days, I'll put together a 2nd generation mold. Once that's done and (hopefully) proven successful, I'll begin parts production and offer them for sale.

Am still learning what works, but fingers crossed for success this week!

-- aae83

Re: Hellcat Radar Pod - 3D printer project

Posted: Sun Nov 20, 2011 6:47 pm

by flyboy_fx

Hey, bubbles are what resin kits are all about.

Man, If I pick up a hellcat, I really want one of these!!!

Top notch work!

Re: Hellcat Radar Pod - 3D printer project

Posted: Mon Nov 21, 2011 4:25 am

by gburch

Looks REALLY good!

Re: Hellcat Radar Pod - 3D printer project

Posted: Mon Nov 21, 2011 9:55 am

by JOC

aae83:

Hope you didn't feel pushed by my post. Still keenly interested in this and am waiting for the time to place my order.

Thanks again and have a nice and safe Holiday.

JOC

Re: Hellcat Radar Pod - 3D printer project

Posted: Mon Nov 21, 2011 11:55 am

by aae83

No worries, JOC. I'd gotten involved in other projects and had just gotten back to this one a week ago. Your question was very timely, as I finally had something worth sharing. The interest/encouragement is greatly appreciated!

It was a bit of a trick (for me, anyway) conceptualizing a 2-part mold that would put the parting line on the mating surface, rather than somewhere on the part exterior. After making and trying the first concept, I realized there were issues with it, and have since invested some brain cycles in concept 2. Am ready to dive in on that one today, and truly expect to be ready by next week, particularly with time available this coming weekend.

Cheers, and more soon...

aae83

P.S. Thanks also for your support, flyboy_fx and gburch!

Re: Hellcat Radar Pod - 3D printer project

Posted: Wed Nov 23, 2011 5:52 pm

by Ara

aae83: Fantastic work! What a wonderful niche product.

Would this fit the Corsair as well?

Re: Hellcat Radar Pod - 3D printer project

Posted: Thu Nov 24, 2011 8:57 am

by aae83

Ara wrote:Would this fit the Corsair as well?

Hi, Ara.

If it does, it would be coincidental: I used wing sections from the Hellcat to size the cutout in the pod and it fits pretty tightly. My Corsairs are boxed up and buried, or I'd just try it.

I think the shape is a little different between the two, also. Looks like the Corsair radar pod has a length of constant diameter that I didn't see in the Hellcat photos. Here's a photo (not mine) of a model kit F4U-5N model radar pod for comparison:

Good question, though; thanks for asking!

-- aae