The following file will both explain and support BBI’s decision to make the landing gear on their 1:32 scale F-4 removable. We did not want to do the same, but we were and if produced, are going to follow suit. We like more detail over unreliable design on our aircraft. Keep It Simple Stupid was lost somewhere along the way. I like the decision of BBI and from the following photos you too may see why I totally support their decision.

Following is a small description of the F-4 and troubles we had in the decision of this great aircraft:

Here is the Admiral Toys’ 1:18 scale F-4. What I will show in this file is the difficulty of manufacturing landing gear to both fulfill the need of a highly accurate model versus a toy that has the landing gear articulate, move up and down.

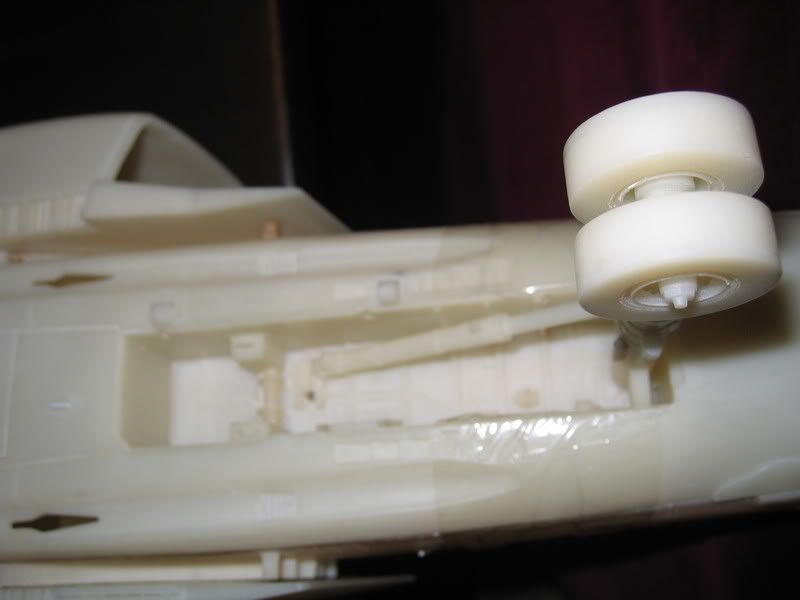

In the above photo you will notice that one of the struts is a lot thinner then the other. This is because of moths on discussions on how to make the landing gear rotate up and down and retain the look of the F-4 that is expected. No the thin strut would not make it into final production. I will explain a little later.

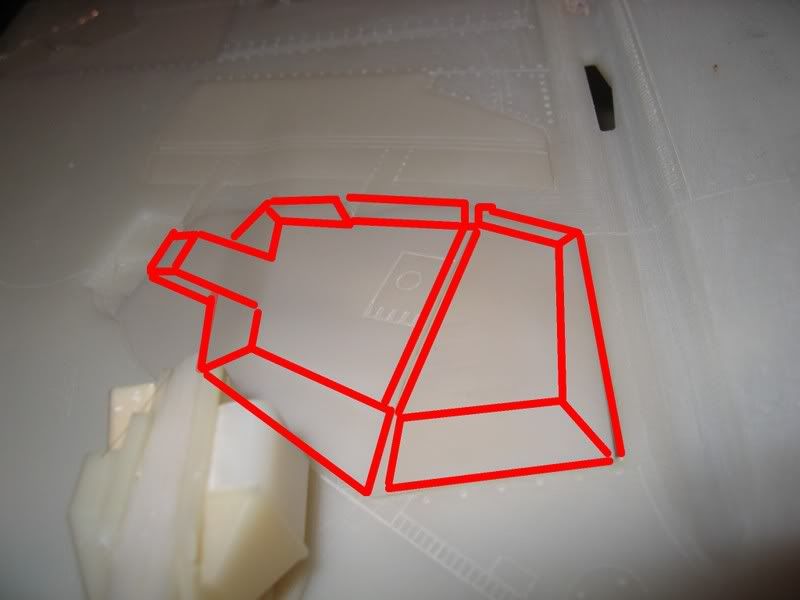

Look how small the area is that has to fit these massive landing gear.

We chose to recreate the F-4 C,D,J. With minor changes we are able to produce these three models. The major reason we chose the CDJ versions is for a particular paint scheme that we had planed to produce in one of those variants. Secondly, the landing gear are all the same on these models. The B version had much narrower landing gear struts and tires that required no modification in the 1:1 of the wings to hold them in the closed position. When the C and beyond models were developed they change the landing gear struts and wheels to support hard field and soft field landings as well as the previous carrier landings. This required a stronger undercarriage and thick struts and tires. Even in the 1:1 model they engineered a noticeable hump in the upper surface of the wing to hold the larger gear.

As you can see there is very little room to fit the landing gear into the well. The doors on the 1:1 have a hump that assists but it does not translate into the 1:18 models. Our plastic is too thick to get away with the same engineering. We would have to change the appearance to get the fit.

In this photo you can see the noticeable hump that is engineered into the bottom side of the wing. We were going to try and exaggerate it by changing the height of the hump on both the underside of the wing and the upper surface of the wings in these locations:

and here:

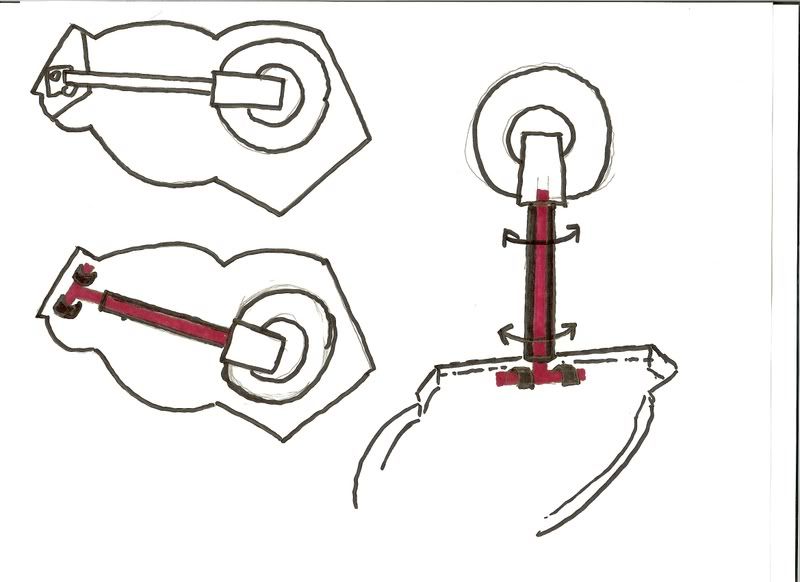

Please forgive my amateur drawings on the computer. China had a good laugh as well. But they get the point. I asked that they change “gradually” the upper surface of the wing from .01 to 2 millimeters and the under surface by 2 millimeters. That is how much more room is needed to fit the struts and fat tires in the wing.

Now you can laugh at my amateur drawings. Here is another problem with the landing gear for the F-4. As you can by the above photos they have a complicated closing angel. They rotate before locking into position. Not to difficult, but if you think about the weight of this model, there is a lot of plastic being help up. So the more complicated the landing gear the more likely they are to fail.

This leads me to why you see a thin strut in a lot of these photos. That part is designed to be metal and have the decorative strut surround done in Plastic. We do not want to do the entire strut in metal because (1) you lose definition and (2) cost.

Look at this photo again. It pretty much sums up the problems.

1. Look at the right tire. Notice its fat and mean appearance. But then look at the left tire; notice how it looks tin and wimpy. Unfortunately the left tire is the only size tire that would fit in the wing if you wanted to retain the 1:1 appearance of the thickness of the wings. I know you would have had a lot to say if we put that tire on our aircraft!

2. Look at both tires and notice that the plastic is bent and compressing against the tires where the tire attaches to the strut. This is because of the massive weight of this aircraft. And this model has no ordinance, paint, pilot, or pressure from your hands that would not be able to stay off this awesome model. Therefore the metal gear would be necessary. Metal does not like to bend and rotate like plastic. Plastic is more forgiving. Therefore, the movements this landing gear require, if made articulating, would have been impossible for a solid metal landing gear. Plastic with a metal shaft inside is more appropriate.

3. Just look the above photo. As messed up as the aircraft is in that photo… it is one awesome aircraft in 1:18. I cannot wait to pick one up for $89.99 from 21st.

The front landing gear does not have a problem:

.

.I was interrupted while producing this file and have to cut it short. I hope I did not waste my time, and more importantly your time, with this post. I hope you enjoy seeing a little more into the process. When I have more time I will continue my discussion of the F-4 and other aircraft.

Regards,

Jason