I wanted to give you a little look into how we made this aircraft and to show you why at times it takes a little longer then you expect to have a completed model.

One of the largest obstacles is to satisfy the demands from the collectors that expect the most accurate aircraft possible for a cheap price. This is not the easiest process. There are no less then 300 parts to each one of our aircrafts. Having these parts come together to form a accurate model takes some time.

You may ask how I design these aircrafts. What sources we use to produce a model. Well here are just a couple of the photos from my personal files that were used to make the SBD. These are just 5 or 6 photos of no less then 1000 photos and materials used in the design of the SBD. It takes a while for China to grasp the concept of a project. Funny story as an interlude: I was in China looking at the ME 262 a couple of years ago and did not like the gaps on the engines where they met up with the wings. I explained the problem and their response was. “We have to have this gap to get the bombs off the wing.” I went on to explain that those were engines and they were to be permanently affixed to the aircraft… So you see. We have people making these models that have never been on an airplane, and no doubt had never seen a 262 or SBD in their lives. It takes some time to get on the same page. Asking our master modelers to change one panel line takes about 5 pages of drawings, photos and explanation from me, 9,000 miles away.

This being said, here is some examples of the notes we send back and forth and a look at a model in its early stages.

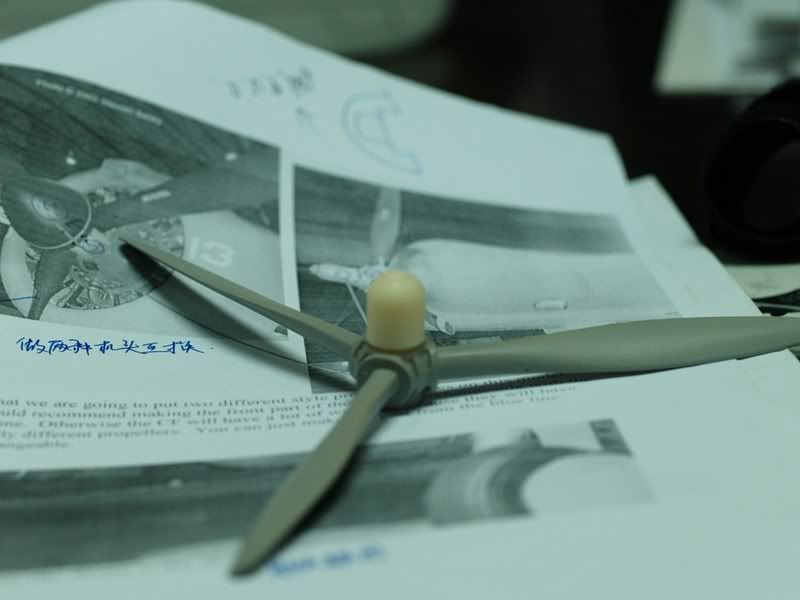

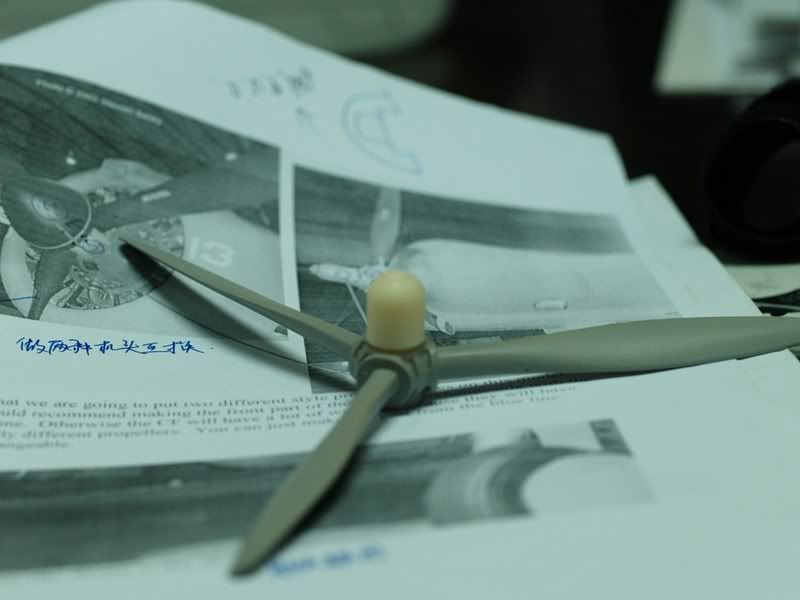

This is a photo of the SBD 3 variant propeller. You may notice in the background a photo of the real thing. We use a lot of photos to produce these models. Many companies simple send a 1:32 scale model and say copy… yes this is easier, but you get the mistakes in those models that the original company incorporated. We prefer to use photos and drawings of the actual subject. I think this makes our models kind of special. We truly make a SBD from nothing.

If you can read Chinese then you have an insight into what the revisions were.

Here is a photo of the SBD 5 variant propeller that will come out soon after the 3. Again, notice in the background the photo of the original. Walk around books are a life saver in this industry.

Preliminary photo of the bombs for the SBD

No you may say that was easy. What else can come from this photo and file? Well let me explain. We have a pretty good example from this photo. I was happy with it, but I did have them narrow down the thickness of the fins, and changed the shape of the propeller on the bomb. Then we have to make decisions. How are we going to attach this bomb to the aircraft? The hard points, should we have them removable? We decided that they will be permanently attached at the factory on this model. Then we have to decide how to attach the bomb to the hard points. Do we use the peg and hole design? No, my BBI F-16 told me that this will not work. Do we use a post and notch design, like on our F-86? No, after several production runs those things seem to move, expand, contract and just flat out frustrate us. So we decided to use a fastener that allows for the bomb to clamp onto the hard point. This allows for a very realistic design that works well. But now we have a problem. We can not clip ABS plastic to ABS plastic. Therefore one piece has to be ABS and the other PVC, or soft plastic. This allows for a Squeeze, Grasping Clamping Type Attachment Point, I coined that name. You may not use it without my expressed consent. So you can see that there are a lot of decisions that must go into a simple little part. Imagine the discussions 21st had regarding the folding mechanism on their beautiful Avenger…

In this photo I am explaining that the thickness of the cowling wall must be thinner. If it was already tooled we would be in trouble at this point. But at this stage the master modeler simply takes a file and shaves off the wall to the desired thickness. Every millimeter of this aircraft is looked over for the smallest modifications. Get them done while you can because these things are pretty much written in stone (steal) once they are tooled.

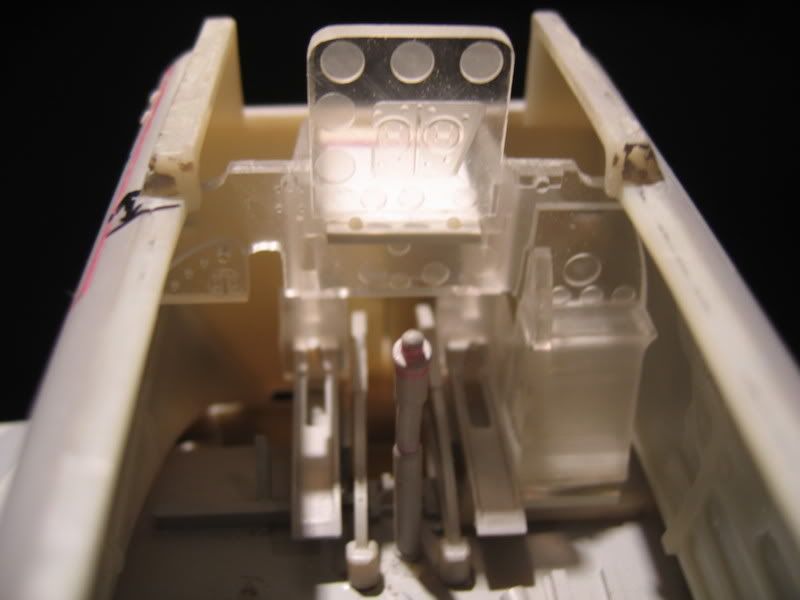

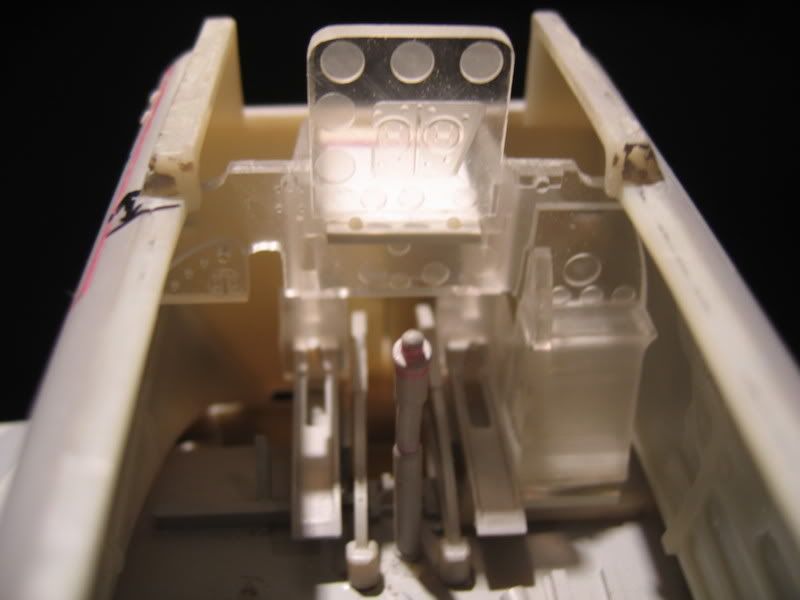

Early photo of the interior

Notice a little surprise that has not been mentioned by me? Someone find the special touch that is apparent from this photo.

Further along in the process you can see more of the detail has been added. Yes there will be gun handles in the aircraft. Those are separate pieces that are added later.

Here is a photo of a cowling in mid modification. The vents were not correct so I had them change the thickness and shape. Notice all the modelers clay that is used to fill, shape and modify the parts. This is sanded off to the desired shapes and design.

Here is the same cowling as above in a mid modified form. Even after all that sanding and talks about shape of the vents I am not satisfied with this photo. You can see that a panel line is not completed, and the length of the cowling protuberance is not correct. It has been modified. Sorry, it was done on computer and I do not have a photo to show you. But you can see from the above photo, it looks pretty good without the modifications.

Paint master for the Military Toy Shop's SBD. It is a great aircraft with a historical past. This is a pretty cool plane.

Pretty nice 1:1 display of the SBD, well A-24 Banshee. I used a lot of photos from this aircraft to assist the factory in some of the fine details of the SBD. Notice its short stance. And this is a museum piece with no fuel and no live bombs. Not a very tall aircraft.

So you can see that a lot of work goes into the model. It has taken longer then expected and we are disappointed in that fact. But this board has a lot to do with the delay. As stated in my quote in an above post, we redesigned the tires, wheels, struts, wheel wells, and wings to give it a better stance, per your request. If you think it takes a lot of steps to determine how to attach a little bomb, imagine the discussions on an entire underside overhaul! But it is well worth it. We want to give you a model that you like and appreciate.

I am sorry that this is not exactly what you wanted from this post, but I wanted to give you at least a glimpse into the SBD and its development. It is underway and will be out when it is ready. Can I give you a date, no. But I promise you that we are working on it as fast a possible without sacrificing quality. It will be ready for T1 injection soon. After that you will start to see more information and final examples of the aircraft. T1 is a technical injection to see how the molds are taking the plastic.

Now in defense of Military Toys Shop, they are a great group of guys and they put up a lot of money out of their own pockets to fund the initial project. This is a very expensive project and with their assistance, together, we are making the SBD a possibility in 1:18. I understand your frustration with pre-orders, but I promise you that it is no where near the frustration The Military Toys Shop is experiencing. They just want to give you a great model. However the ball is in Admiral Toys' court. Blame me for your frustrations. I will work as hard as possible to remedy the delays.

P.S.

It took me a long time to write this post so I missed out on what Isaiah said in response to this thread. See I told you they are a great group of guys to deal with! Great customer feed back Isaiah. Keep up the good work over there. Your model is coming as soon as possible.

Regards,

Jason